Custom Metal Fabrication

Custom Metal Fabricator Victoria BC

The process of custom metal fabrication begins with taking raw metal and then working with it, cutting and shaping it, transforming the metal different shapes, sizes, and pieces for a multitude of uses from simple hand tools to much larger items and products. Typically, this process is followed to manufacture things such as industrial machinery, or pieces for industrial machinery.

The only limitation with custom metal fabrication is the imagination of the customer. From a unique metal tool to custom crafted driveway gates, to large pedestrian bridges and metal staircases, whatever they can imagine, if it can be made out of metal, then we can do it. There are multiple steps involved in the fabrication process.

Shearing

It all starts here with the shearing process of custom fabricating. This involves cutting large metal panels or pieces of steel, aluminum, iron, or whatever is the metal being used, in to smaller, more manageable sheets or pieces. Smaller metal sheets can usually be cut by hand. However, when it comes to the task of shearing multiple metal sheets, the most accurate results can be achieved by cutting the sheets by machine wherever possible. Simply because shearing makes metal easier to manage, it is an essential first step in this custom fabrication process.

Forming

The second step of the process is known as forming. Here is where we take the previously cut metal, and then shape and bend it in to required shapes, forms and items. We achieve this with the use of dies or other materials, designed specifically for our purposes. In this process, metal is being transformed from a flat piece of metal by being bent and formed in to a 3-dimensional shape. When working with softer metals, the strength of human hands may be enough to bend and form it. Otherwise, there are various tools and machines that can be used to work with the harder metals.

Grinding

The third step of the custom welding process is grinding. This is a finishing stage for the formed product or item. So once the metal is bent and welded in to place, there can be rough edges and little shards of metal that need to be removed. Grinding accomplishes this on whatever metal part being worked on. Grinding removes any sharp edges, and also round outs overly pointy corners, ensuring that that the finished metal pieces are safely handled by the end user.

Finalizing

As the word alludes to finalizing, is the fourth and final step in the custom metal fabrication process. This is where we are inspecting the finished item and are looking for flaws, irregularities, or any rough spots that may have been missed somewhere along in the process.

This is a very important part of the finalizing process as it’s our last chance to grind them down and smooth them out before we turn over the product to the customer. We will also paint and treat the metal, if its part of the design. We often add a sealant for protection as well, just to help increase the lifespan and look of the metal. After all these steps are successfully completed, the time comes that we ship off the metal part to whatever we’ve manufacture to the client who ordered it.

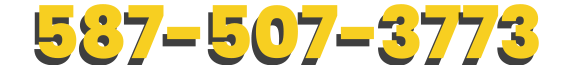

Give us a call and speak to one of customer service agents and we’ll be able to begin assisting you with your next project without any further delay. We cannot wait to start helping you with your custom metal driveway gates.

587-507-3773

Red Deer Welding Pros

Serving Red Deer, Sylvan Lake, Red Deer County, and Central Alberta

Working hours

- Mon - Fri

- -

- Sat - Sun

- Closed